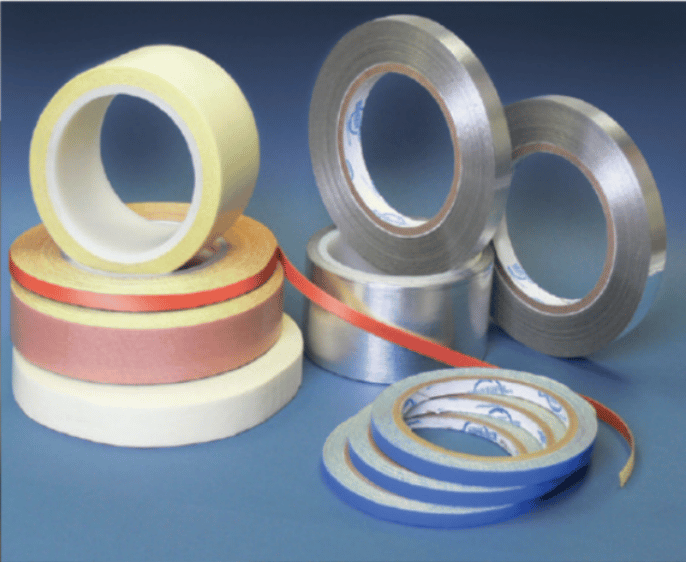

Thermal Spray Tapes

Thermal spray masking tapes are designed to stick tenaciously and enable clean removal even after exposure to high temperatures. For metal or ceramic plasma spraying, arc spraying, metallizing, HVOF, and grit blasting, thermal spray tapes create a protective mask.

- Conforms easily to parts with complex geometries

- Clean removal after spraying

- High temperature masking

- Excellent protection during grit blasting

Request for Quote

DETAILS

When thermal spraying is required, shielding mission-critical components from overspray and splash might be difficult. No matter the spray angle, base metal, temperature, or substrate, thermal spray solutions shield components from even the most relentless bombardments. Thermal, Plasma, and HVOF tapes create a protective mask for metal or ceramic plasma spraying, arc spraying, HVOF, and grit blasting and are devoid of carbonising components. Thermal spray masking tapes are designed to aggressively attach, guarantee sharp edges, and remove swiftly and thoroughly. There are single- and double-ply versions of these items available. Our double-ply tapes provide a cost-effective alternative to multi-layer masking even in the most demanding situations.

Specifications

Single Ply

| Product Number | Backing | Backing Thickness | Adhesive | Adhesion oz/in | Engine Manufacturer Approvals | Max Temp ℃ |

| DW407 | Aluminum Foil / Glass Fabric | 5 Mil | Silicone | 63 | Pratt & Whitney PMC 4235 Rolls-Royce Aero Repair OMAT2/205 Lockheed Martin J505 |

260℃ |

| DW411 | Aluminum Foil / Glass Fabric | 7 Mil | Silicone | 74 | Pratt & Whitney PMC 4235 Rolls-Royce OMAT2/96L General Electric C10-12 |

260℃ |

| DW468-7 | Glass Fabric | 5 Mil | Silicone | 30 | Pratt & Whitney PMC 4614 Rolls-Royce Aero Repair OMAT2/204 |

260℃ |

| DW497 | Silicone Rubber / Glass Fabric | 9 Mil | Silicone | 43 | Pratt & Whitney PMC 4458 Rolls-Royce OMAT2/96L General Electric C10-12 |

260℃ |

| DW500 | Silicone Rubber / Glass Fabric | 9 Mil | Silicone | 49 | Pratt & Whitney PMC 4630 PMC 4295 Rolls-Royce OMAT2/96M General Electric C10-12 |

260℃ |

| DW500R | Silicone Rubber / Glass Fabric | 9 Mil | Silicone | 49 | Pratt & Whitney PMC 4630 Rolls-Royce OMAT2/96M |

260℃ |

Double Ply

| Product Number | Backing | Backing Thickness | Adhesive | Adhesion oz/in | Engine Manufacturer Approvals | Max Temp ℃ |

| DW496 | Foil / Glass Cloth | 15 Mil | Silicone | 63 | General Electric C10-12 | 260℃ |

| DW498 | Silicone Rubber / Glass Fabric / Foil | 21 Mil | Silicone | 63 | Pratt & Whitney PMC 4480 General Electric C10-12 |

260℃ |

| DW500-10 | Silicone Rubber / Glass Fabric | 16 Mil | Silicone | 53 | Pratt & Whitney PMC 4630 Rolls-Royce OMAT2/96M |

260℃ |

| DW504 | Silicone Rubber / Glass Fabric | 28 Mil | Silicone | 52 | 200℃ |

HVOF

| Product Number | Backing | Backing Thickness | Adhesive | Adhesion oz/in | Engine Manufacturer Approvals | Max Temp ℃ |

| DW411 | Aluminum Foil / Glass Fabric | 7 Mil | Silicone | 74 | Pratt & Whitney PMC 4235 Rolls-Royce OMAT2/96L General Electric C10-12 |

260℃ |

| DW500-40 | Silicone Rubber / Glass Fabric | 42 Mil | Silicone | 57 | 260℃ | |

| DW501 | Silicone Rubber / Glass Fabric / AL Foil / Glass Fabric | 24 Mil | Silicone | 76 | FAA Regulations GE-Standard Practices Rolls-Royce OMAT2/96M | 260℃ |

| DW503 | Copper Foil / Glass Cloth | 36 Mil | Silicone | 25 | 260℃ |

APPLICATIONS

Components, parts, and equipment are protected by protective coatings from extremes, notably the weather and temperatures. Because they can perform a variety of tasks, thermal sprayed coatings are frequently used on aeroplanes. Things that have been thermal sprayed with a protective coating will be less affected by humidity, rain, and other environmental factors. Another industry that commonly employs these coatings is the automobile sector.

Resurfacing

Reclamation and re-engineering of a wide range of rotating and moving components from equipment that is prone to wear, corrosion, or erosion, including machines of various shapes and sizes. Arc spray, flame spray, or high velocity oxygen furnace (HVOF) systems are used for this to spray steels, nickel alloys, carbides, stainless alloys, bronzes, copper, and many other materials.

Enhanced surface properties

Provides additional benefits of enhanced surface properties. Such as dielectric coatings, release coatings and traction coatings.

Erosion & Corrosion Resistant

A wide variety of components that operate in harsh settings where erosive forces like heat, corrosion, wear, and abrasion work together to shorten component life are covered with thermal sprayed coatings.