Capabilities

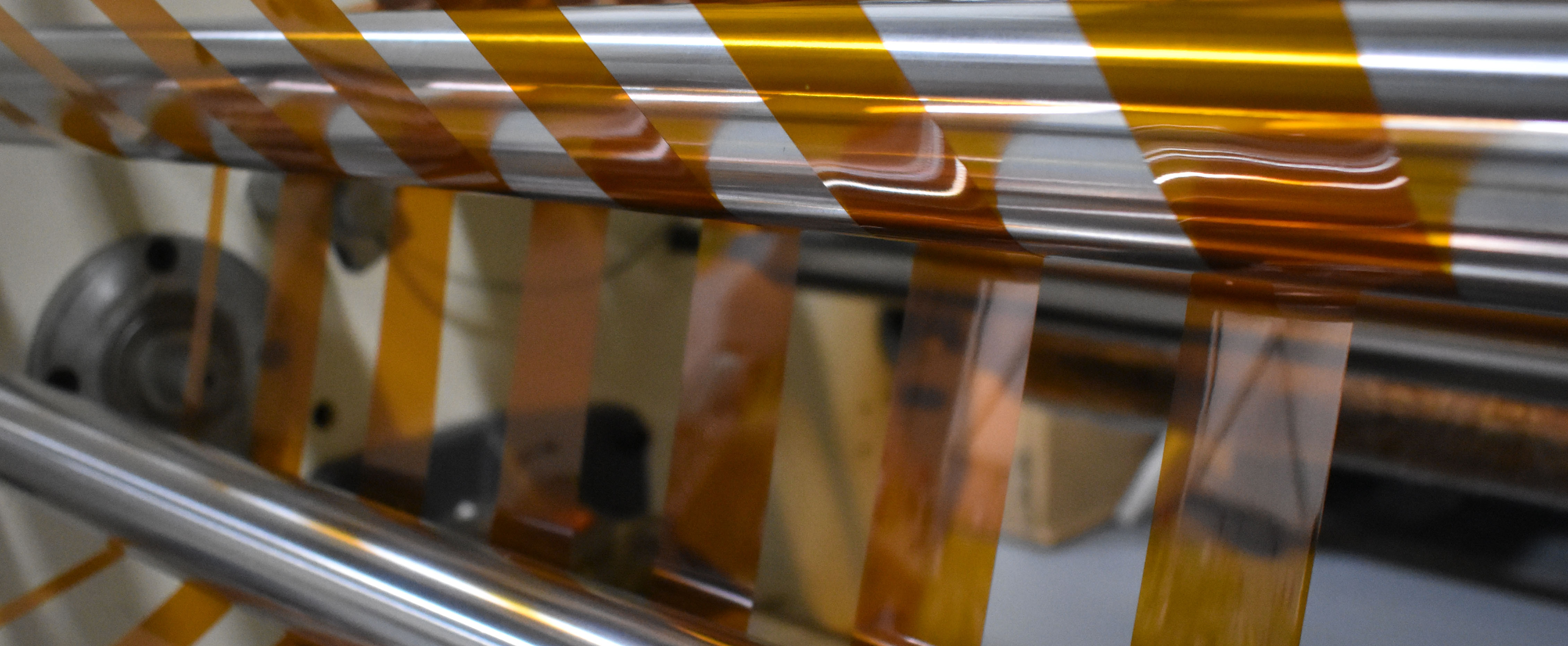

Slitting

This Is What We Do

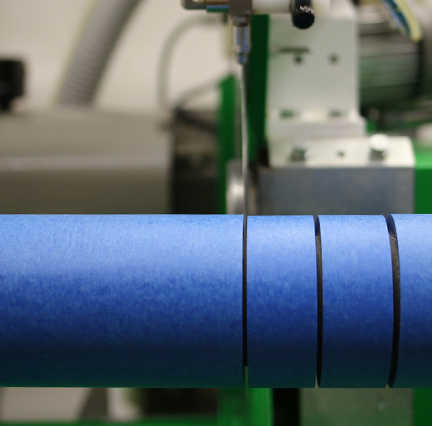

Lathe Slitting

Specifications

Width range from 0.03″ up to 50″.

Tolerances of up to +/- 0.003″, depending on the material.

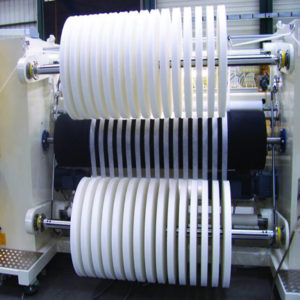

Rewind Slitting

Rewind slitting is more efficient because it can produce multiple cut rolls from a master log in one cycle. First, the machine unwinds the master roll, then it is fed through a series of blades. Next, the winds each section onto a new core, creating a new slit roll. CGS utilizes common styles such as score, shear and razor.

- Score style cuts material by pressing a set of circular blades against a metal mandrel, after which, the material is pulled through the blade. Score slitting is more appropriate for materials of inconsistent thickness.

- Shear style also uses a set of circular blades. The material is slit at the the junction of the two blades. It is ideal for paper, foil, and heavier gauge materials.

- Razor style uses a set of stationary blades positioned across the machine. The machine pulls the material through the blades, while cutting it in the process. Razor style is best suited for films and thinner materials of consistent thickness

Specifications

Width range from 0.25″ up to 50″.

Tolerances of up to +/- 0.003″, depending on the material.

Benefits of Die Cutting

Save time for production

We have been in operation since 2000, and we have had the pleasure of helping hundreds of clients. Along with our products including Kapton tape and Polyimide film, we also provide services such as slitting and laminating.

Uniformity, Accurate and Repeatable

Our customers are our top priority. We strive to build long-lasting and meaningful relationships through our products and services. We look at each customer as a partner, because we genuinely believe that their success is our success.

Complex Shapes

Beyond positive reviews and excellent customer feedback, we are a fully certified and accredited company who can supply and convert insulation films and tapes.

Lower Cost

Everything we do at CGS is fast. Same day shipping, quotes, prototype & answers.

Die Cutting Materials

Die cutting is ideal for a variety of materials because of its efficiency, including:

- Polyimide

- Polyester Tape

- PTFE

- Adhesive

- PVC

- Paper

- Glass Cloth Tape

- Foil Tape

Markets Served

Many industries benefit from the use of slit materials, because it saves time and money. For example:

- Electronics

- Automotive

- Medical

- Specialty industries Manufacturing

- Powder Coating

- Aerospace

Get In touch

(905)836-6668

Address 1119 Ringwell Drive, Newmarket, Ontario, L3X 2H8

Email info@cgstape.com