Capabilities

Laminate

This Is What We Do

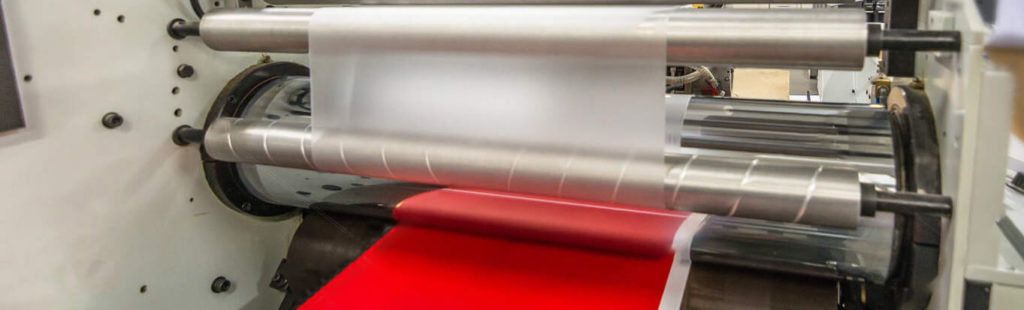

CGS also offers laminating services, it is the process of manufacturing multiple layer materials joined by using adhesives. CGS has multiple laminating machines to perform laminating services for a variety of film and adhesive tapes. The finished product gains improved strength, appearance or other properties. These material can then be further converted for ease of use, by die cutting, slitting or sheeting.

MATERIAL LAMINATING

Many CGS products requires the laminating of two or more materials. For example, laminating adhesives to film to create adhesive tape. We can also laminate multiple layers together creating a thicker version of the same material. For example, our 20 mil Kapton film, that is used to replace Cirlex.

SPECIFICATIONS

Max width of 24″

Single layer and multi layer lamination

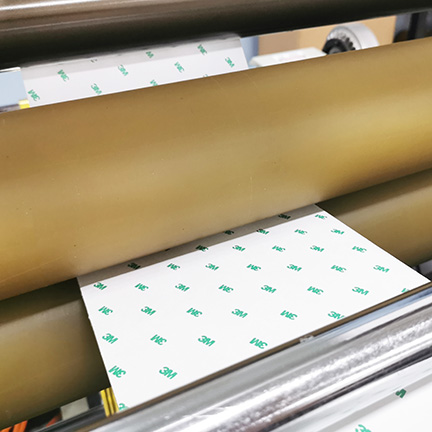

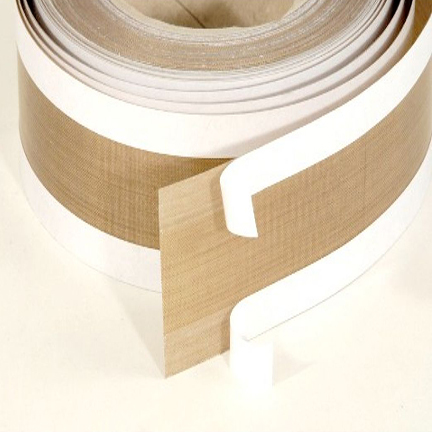

ZONED ADHESIVE LAMINATING

CGS also provides zoned lamination services. It is a special technique that creates a partially adhesive covered tape. This is achieved by laminating pre-cut adhesives onto the substrate. Alternatively it can also be done by pulling away the unwanted adhesive from the finished part. The precise zone of adhesive allows for secure bonding while the uncoated zone prevents any adhesive contacts.

SPECIFICATIONS

Max width of 24″

Single layer and multi layer lamination

Benefits of laminating

Ability to combine different material properties

Increased material options, like strength and appearance.

Offer different thickness of materials instead of the standard products.

Laminate Materials

Laminating is ideal for a variety of materials:

- Polyimide

- Polyester Tape

- PTFE

- Adhesive

- PVC

- Paper

- Glass Cloth Tape

- Foil Tape

Markets Served

Many industries benefit from the use of laminated materials, because it saves time and money. For example:

- Electronics

- Automotive

- Medical

- Specialty industries Manufacturing

- Powder Coating

- Aerospace

Get In touch

(905)836-6668

Address 1119 Ringwell Drive, Newmarket, Ontario, L3X 2H8

Email info@cgstape.com