Capabilities

Sheeting

This Is What We Do

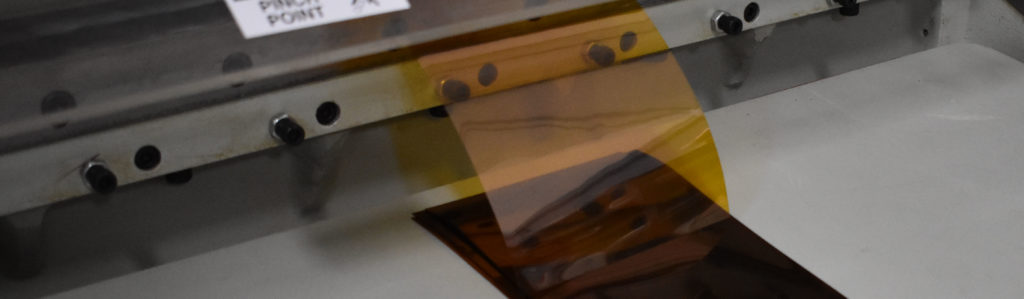

The process of plastic sheeting involves converting a flexible material into flat, individual pieces/sheets. This allows for pieces to be precisely cut to the desired length as opposed to being wound on rolls. Due to the nature of the machine and the speed of the process, sheeting saves time and improves consistency in the material. We at CGS can provide customers with the alternative of pre-cut pieces along with rolls of material. Choosing CGS will ensure that there is no need for additional cutting, and sheeting provides an easy and simple way to handle large pieces of adhesive tapes and films.

GUILLOTINE PLASTIC SHEETING

Flatbed die cutters use a hydraulic press to press a die down on the material, piercing through the material and forming the desired shape. This is the most popular method because the tooling costs less, making it ideal for shorter runs where the cost of a rotary tool is prohibitive. CGS also has the capability for in house steel die manufacturing, providing cost saving on new dies and quick turnaround.

SPECIFICATIONS

Max width of 40″

Max thickness 1/4″

Benefits of Plastic Sheeting

Save time for production

converting material to sheets for direct use, thus saving valuable time and energy.

Sheets will stay flat, thus reduce curling of materials

Sheeting Materials

Sheeting is ideal for a variety of materials because of its efficiency, including:

- Polyimide

- Polyester Tape

- PTFE

- Adhesive

- PVC

- Paper

- Glass Cloth Tape

- Foil Tape

Markets Served

Many industries benefit from the use of sheet materials, because it saves time and money. For example:

- Electronics

- Automotive

- Medical

- Specialty industries Manufacturing

- Powder Coating

- Aerospace

Get In touch

(905)836-6668

Address 1119 Ringwell Drive, Newmarket, Ontario, L3X 2H8

Email info@cgstape.com