Capabilities

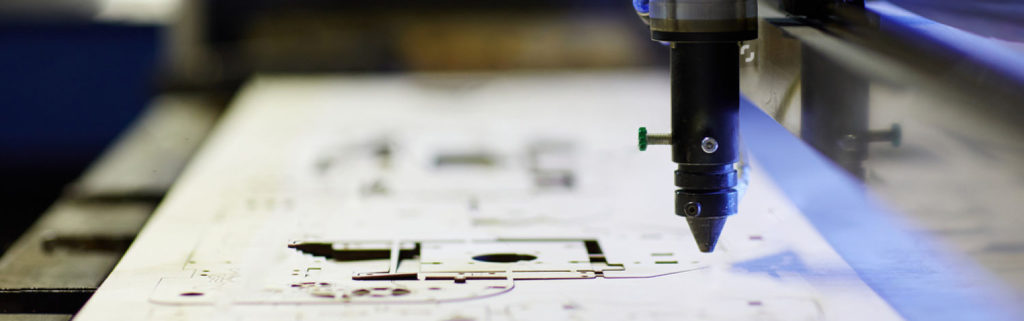

Laser

This Is What We Do

Laser cutting is used for converting material into small parts with very narrow tolerance. The process is highly accurate, yields excellent cut quality, has a very small kerf width and small heat affect zone. It also makes it possible to cut very detailed shapes and small holes.

Laser cutting machines are capable of very tight tolerances (<20 micrometers) and have a repeatability of 5 micrometers. Making them the ideal cutting method for demanding uses.

LASER CUTTING

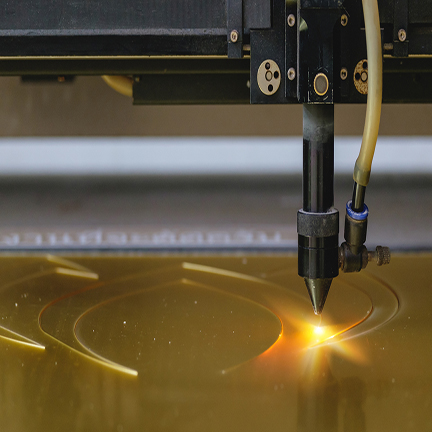

Laser cutting is a thermal separation process. When the laser beam touches the surface of the material, it heats it up to the point that it melts or vaporizes.

Polyimide films and tapes are among the most versatile materials available and are extensively used in demanding industries such as medical, biotech, aerospace, and automotive. The cutting of polyimide (also known as Kapton or Cirlex) with laser systems is characterized by its high level of precision, quick turn around and flexibility.

Specifications

Tolerances of 20 micron, varies with material

LASER EFFECT ON POLYIMIDE, KAPTON AND CIRLEX

Polyimides are excellent absorbers of CO2 laser energy. When the polymer absorbs laser energy, it quickly converts optical energy into heat. The material just outside of the laser’s path will conduct a lot of heat. Thus causing it to become black and carbonized. You can then use Isopropyl alcohol to clean up this black char and residue.

The use of UV laser on Kapton and polyimide is also common. For clean cuts, wavelength is crucial. UV machines match the absorption bands of kapton (10.6 um) and allow for cleaner cutting

Benefits of Laser Cutting

Rapid prototyping because of its easy set up

High precision due to small kerf

No Need for tool costs

Laser Cutting Materials

Laser cutting is ideal for a variety of materials because of its efficiency, including:

- Polyimide

- Polyester Tape

- PTFE

- Adhesive

- PVC

- Paper

Markets Served

Many industries benefit from the use of laser cut materials, because of the high precision. For example:

- Electronics

- Automotive

- Medical

- Aerospace

Get In touch

(905)836-6668

Address 1119 Ringwell Drive, Newmarket, Ontario, L3X 2H8

Email info@cgstape.com