Request for Quote

DETAILS

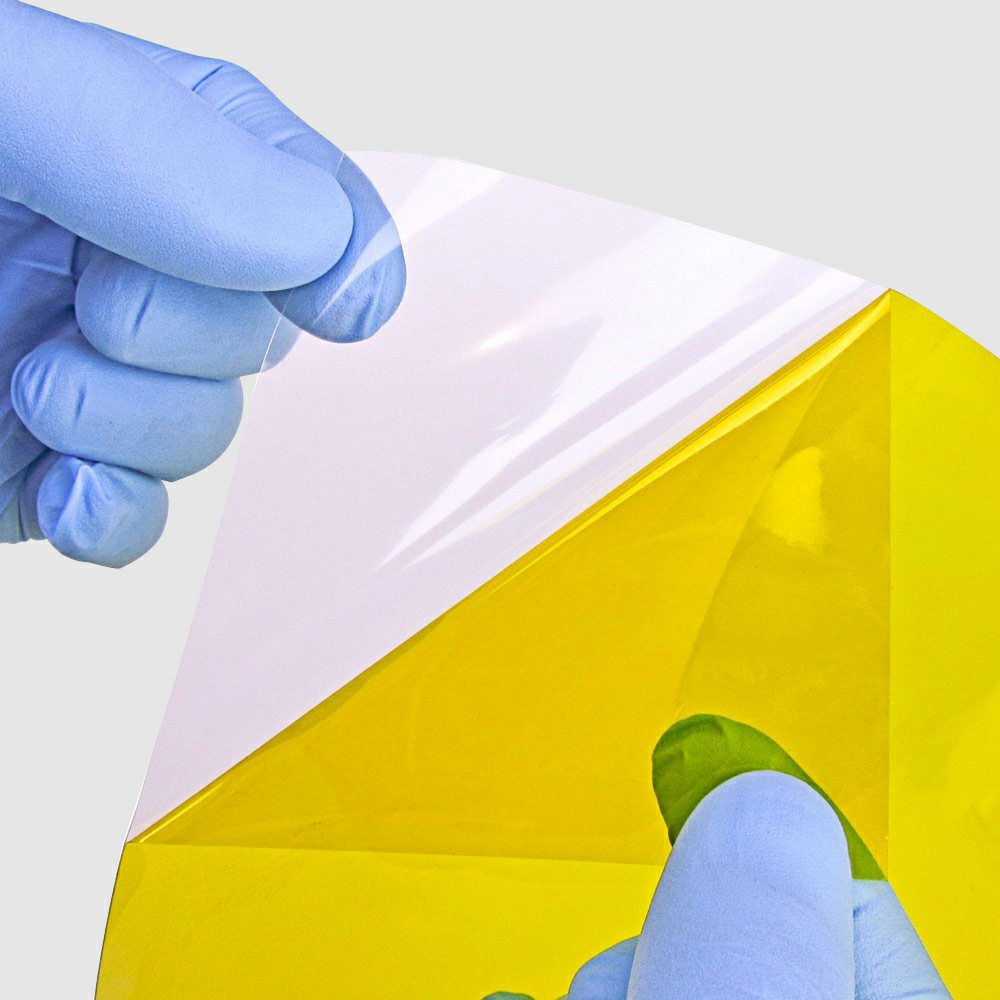

Polyimide high temperature tapes with liners are manufactured by coating the polyimide film with a desired adhesive system, with the film thickness ranging from 0.5 mil to 10 mils, adhesive thickness of 0.5 mil to 2 mils. CGS has the capabilities to coat both silicone and acrylic adhesives that remove cleanly, leaving no residue in high temperature applications. It has been used in applications at temperatures up to 300°C (560°F). It has high performance, reliability and durability, with a unique combination of electrical, thermal, chemical and mechanical properties that withstand extreme temperature and other demanding environments. With the added easy release liner, this material is ideal for die cutting applications and is much easier to handle.

Specifications

| Product Number | Polyimide Backing Thickness | Adhesive | Total Thickness Mils | Liner | Adhesion to Steel oz/in | Dielectric Strength Total Volts | Operating Temperature ℃ |

| CGSTAPE-8558 | 1 Mil | Silicone | 2.5 | Clear PET | 25 | 6500 | 260℃ |

| CGSTAPE-8658 | 2 Mil | Silicone | 3.5 | Clear PET | 25 | 11000 | 260℃ |

| CGSTAPE-8758 | 5 Mil | Silicone | 6.5 | Clear PET | 25 | 18000 | 260℃ |

APPLICATIONS

Powder Coating Masking

High temperature polyimide masking tape is ideal for powder coating masking application. It is coated with a high temperature silicone adhesive, with the aggressive adhesive having clean removal capability. The liner allows for easy handling of the material, making the masking process more convenient, especially on large projects.

Die Cutting & Laser Cutting

Polyimide tapes with liners are useful for making custom powder coating stencils or masking die cuts on plotters or die cutting machines. This is a perfect way to cut costs and speed masking processes in PCB & electronic manufacturing.