Of the top 5 causes of downtime in manufacturing, machine malfunctions are number one. You can attribute this to the fact that most machine parts are metal and are thus susceptible to wear and tear. Even if you keep your tools in the best of shape, there is still the possibility that they can break down at some point during their use.

Fortunately, you can use thermal spray to protect tools and parts from wear and tear. And for the areas that don’t need thermal sprayed coatings, DW500 will help keep them covered.

This article will provide you with an overview of what thermal spray is, how it works, and its many benefits to help you keep your tools and parts in good condition.

What Is Thermal Spray?

Thermal spray is a coating process that’s used to apply a protective layer to surfaces. The thermal spray gun heats the metallic materials to form a liquid slurry that is sprayed onto a surface. You can also use nonmetallic materials for the thermal spraying process. The molten material bonds with any solid surface it touches. This creates a barrier that protects against wear. This material also adds strength and durability to what’s being repaired or protected.

Benefits of Thermal Spraying

The key benefit of thermal spraying is that it lowers your expenses. Most commonly, the material sprayed onto a part will replace worn or damaged areas of the part. This eliminates replacement costs and improves your overall return on investment (ROI) for equipment.

Thermal spray can also enhance a material by improving fatigue resistance when applied thermal spray can increase corrosion resistance as well. It also doubles as an insulation layer in certain applications due to its high emissivity rating.

What Is DW500 and How Is It Used in Thermal Spray Applications?

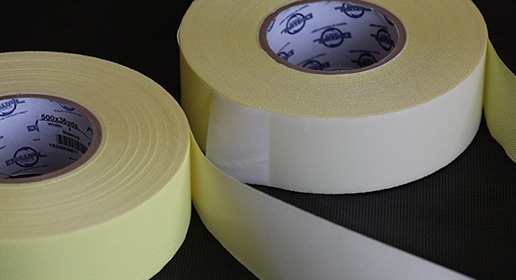

DW500 is a thermal spray masking tape designed for the most extreme thermal spray applications. The strong bond between the DW500 and the substrate provides superior high-temperature protection. An added benefit is that the tape will remove without leaving any residue. The use of DW500 is recommended when there are areas of the surface that do not require thermal sprayed coatings.

Protect Your Machinery During Thermal Spray Applications

Thermal spraying offers a host of benefits to manufacturers, but there are some risks that come with the process. If you’re not careful, you can damage your equipment and cause downtime. To assist in protecting your machinery during thermal spray application, we suggest using DW500 high-temperature masking tape from us here at CGS Tape. Our strong adhesive tape provides excellent thermal protection.

Don’t hesitate to Contact CGS Tape today to ask for a quote or further information on any of our products. We are always happy to discuss on how our thermal protection products can help keep your machinery in good condition.

Get In touch

(905)836-6668

Address 1119 Ringwell Drive, Newmarket, Ontario, L3X 2H8

Email info@cgstape.com