Capabilities

Die Cut

This Is What We Do

Die-Cutting is the process of converting materials into identically shaped pieces by utilizing a die: a ‘stamp’ consisting of sharp blades. The raw material is first mounted on a plate and then run through the machine, where the die is pressed onto the material, creating the desired shape. The speed of the machine and uniformity of the die allows identical products to be mass-produced at a rapid rate. The process also uses custom made dies, so virtually any shape can be die-cut from a material. CGS also utilizes a more sophisticated kiss-cutting technique. It involves cutting through just one layer of material, stopping at a laminated layer or liner, allowing for paper-thin cuts.

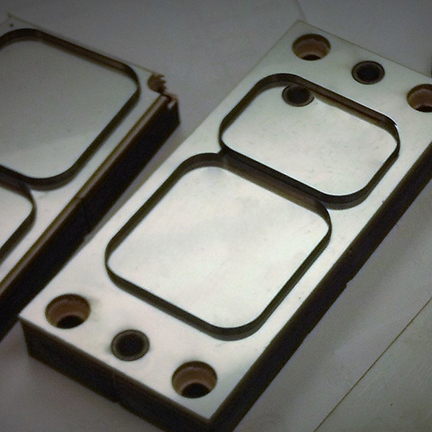

Flat Bed Die Cutting

Flatbed die cutters use a hydraulic press to press a die down on the material, piercing through the material and forming the desired shape. This is the most popular method because the tooling costs less, making it ideal for shorter runs where the cost of a rotary tool is prohibitive. CGS also has the capability for in house steel die manufacturing, providing cost saving on new dies and quick turnaround.

Specifications

Max width up to 24″

Tolerances of up to +/- 0.005″, varies with material

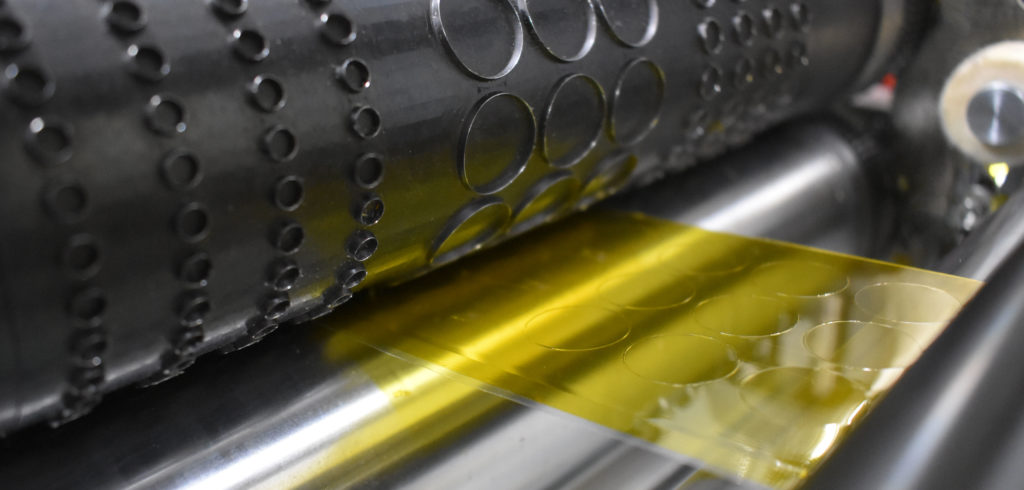

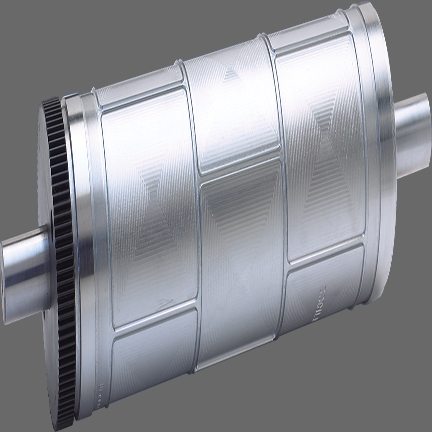

Rotary Die Cutting

Rotary Die-Cutting uses a cylindrical die on a rotary press, and a long sheet of material is fed through the press. This method is much faster than the flatbed method, however rotary dies are more expensive. Thus, this method is ideal for longer runs because the cost of the rotary die gets diluted by the larger quantity and outweighed by the saving on time cost.

Specifications

Max size of 12″

Tolerance of ± 0.005″, varies with material

Benefits of Die Cutting

Save time for production

We have been in operation since 2000, and we have had the pleasure of helping hundreds of clients. Along with our products including Kapton tape and Polyimide film, we also provide services such as slitting and laminating.

Uniformity, Accurate and Repeatable

Our customers are our top priority. We strive to build long-lasting and meaningful relationships through our products and services. We look at each customer as a partner, because we genuinely believe that their success is our success.

Complex Shapes

Beyond positive reviews and excellent customer feedback, we are a fully certified and accredited company who can supply and convert insulation films and tapes.

Lower Cost

Everything we do at CGS is fast. Same day shipping, quotes, prototype & answers.

Die Cutting Materials

Die cutting is ideal for a variety of materials because of its efficiency, including:

- Polyimide

- Polyester Tape

- PTFE

- Adhesive

- PVC

- Paper

- Glass Cloth Tape

- Foil Tape

Markets Served

Many industries benefit from the use of die cut materials, because it saves time and money. For example:

- Electronics

- Automotive

- Medical

- Specialty industries Manufacturing

- Powder Coating

- Aerospace

Get In touch

(905)836-6668

Address 1119 Ringwell Drive, Newmarket, Ontario, L3X 2H8

Email info@cgstape.com